Chrome Anode

Lead-Tin Alloy anodes are recommended for chrome plating. Anodes of chromium metal would neither be economical to manufacture nor technically advisable for chromium plating baths. Because they dissolved at 100% efficiency and increase the chromium content of the bath rapidly, therefore insoluble Lead-tin alloy anodes are recommended.

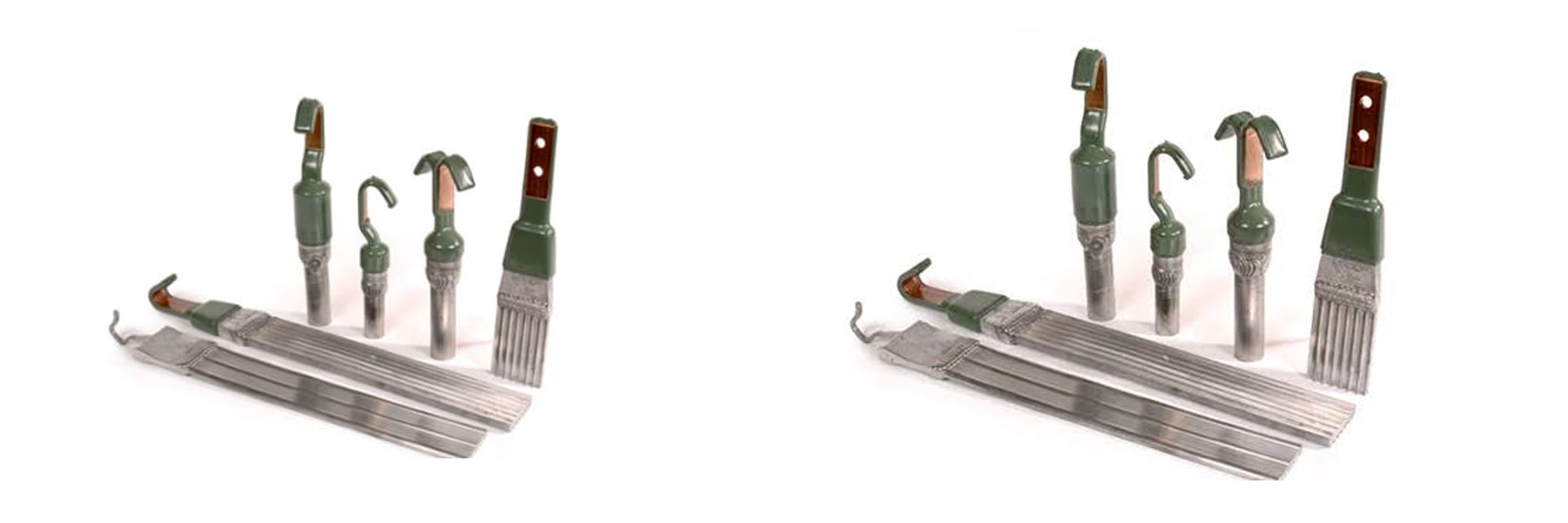

Fluoride type catalyst more curded to led anodes therefore sulfate base catalyst recommended. When the lead anodes operating correctly these should be coated with a chocolate brown film of lead peroxide. During the idling period the anodes become passive with a yellow layer, and this can be cleaned mechanically or by immersing in alkaline cleaner. Round and corrugated anodes are preferred over flat anodes.